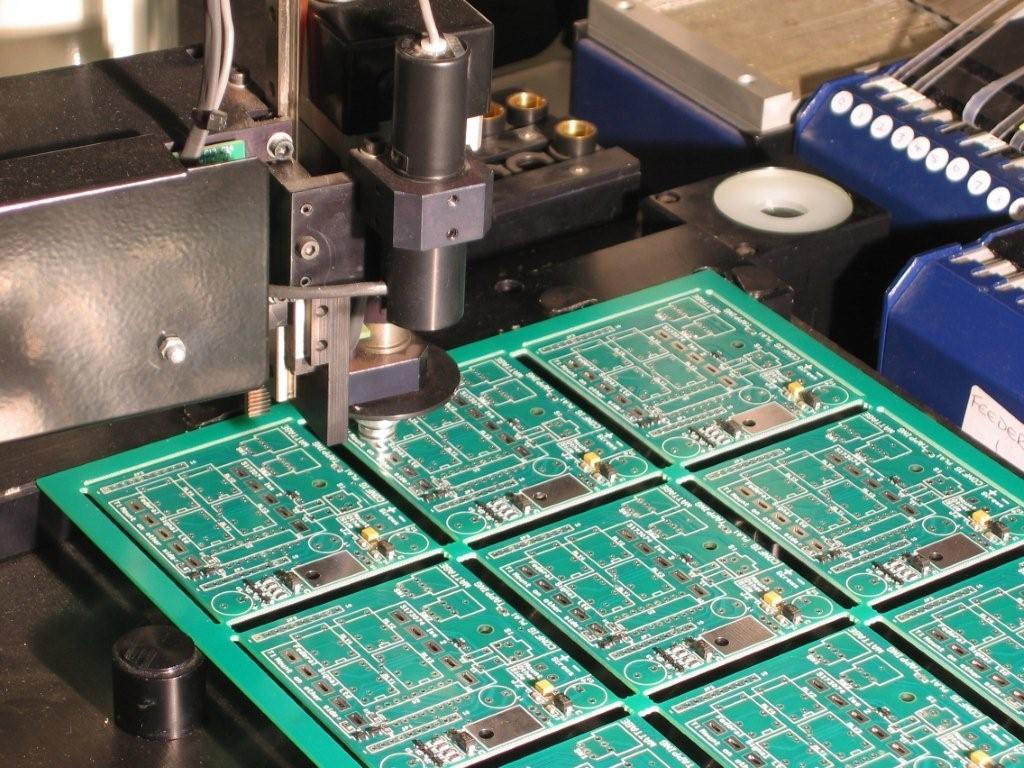

In electronics, efficiency matters. Smartphone, computer, and automotive performance must be maximized while minimizing size and cost. PCB assembly is important to this efficiency. Electronic devices’ operation and performance depend on PCB assembly, which entails assembling electronic components onto a PCB to form a circuit. Explore how pcb fabrication assembly boosts electronics performance and efficiency. First and foremost, PCB assembly allows compact and lightweight designs. Combining electronic components on a pcb allows manufacturers to make lighter, more compact devices without sacrificing functionality. The device’s small size and low weight increase its portability and use.

PCB construction improves longevity and dependability. Manufacturers establish a robust and dependable connection that can endure a range of environmental conditions, including temperature swings, vibrations, and mechanical stress, by soldering electronic components onto a printed circuit board (PCB). This sturdy design lowers the possibility of malfunctions or failures by ensuring that electrical gadgets operate dependably in challenging circumstances. Electronic devices, whether they are medical, industrial, or automotive systems, depend on PCB assembly to function reliably and efficiently in demanding conditions.

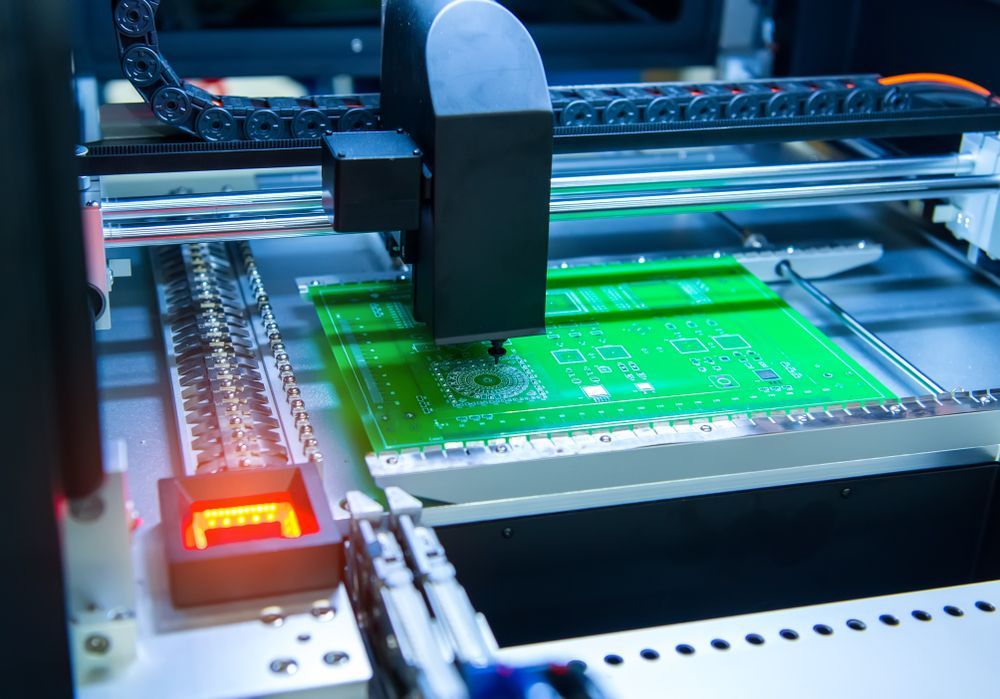

PCB assembly streamlines the manufacturing process and reduces costs. Manufacturers may create electronic gadgets more cheaply and effectively by automating the assembly process.Automated assembly techniques such as Surface Mount Technology (SMT) and Through-Hole Technology (THT) allow for high-speed and high-precision assembly of electronic components onto PCBs, reducing labour costs and minimizing production time. Additionally, PCB assembly enables manufacturers to optimize material usage and minimize waste, further reducing production costs and improving overall profitability.

Scalability and customisation are made easier by PCB assembly. Flexible and scalable design possibilities are made possible by pcb fabricationassembly, which can be used to introduce new features, upgrade current components, or adjust to shifting market demands. Manufacturers can readily alter PCB layouts, replace components, or change production quantities to satisfy particular client demands and market trends. Because of their adaptability and agility, manufacturers are able to react swiftly to consumer demands and market opportunities, maintaining their competitiveness in the fast-paced electronics sector of today.

PCB assembly plays a crucial role in maximizing performance and efficiency in electronics. From compact designs and enhanced reliability to streamlined manufacturing processes and scalability, PCB assembly enables manufacturers to create innovative electronic devices that meet the demands of today’s consumers. By leveraging the power of PCB assembly, manufacturers can create products that deliver superior performance, durability, and value, ensuring success in today’s competitive electronics market.